1.Introduction

The growing demand for convenient and healthy food options is driving rapid market growth for full-automatic tortilla production lines. These linesenable large-scale, efficient production while maintaining high product quality, meeting the market's need for high capacity and reliable supply.The tortillas we commonly call were originally named after Mexico, and the raw material is corn, but corn dough does

not have the ductility and processability of flour dough. Nowadays, when we talk about tortillas, we mostly refer to: flour tortillas, that is, Flour Tortilla Production Line. Compared with corn as the raw material, the processing technology of flour tortillas is much simpler. The tortilla 1200 production line produced by our company is a popular type of thin tortilla made of flour. In addition, there are tortillas, corn-based tortillas and U-shaped burritos.

Integrating advanced automation, a full-automatic tortilla production line automates the entire process, from raw material handling to packaging. This reduces labor costs, enhances production efficiency, and ensures product consistency. For food manufacturers, adopting such a system increases capacity, shortens production cycles, and improves competitiveness.

2.Market background and demand analysis of tortilla production line

"The growing global appetite for tortillas has led to an increased demand for high-capacity, industrial-grade tortilla production lines. These advanced systems are designed to cater to the needs of a market that expects not only a large supply but also the highest quality. The industrial-grade aspect ensures the production line's durability and reliability, while the high-capacity feature guarantees the ability to produce tortillas on a scale that meets the surging consumer interest. By combining these two attributes, manufacturers can efficiently meet the rising demand, maintain product excellence, and secure a strong position in the competitive global food industry."

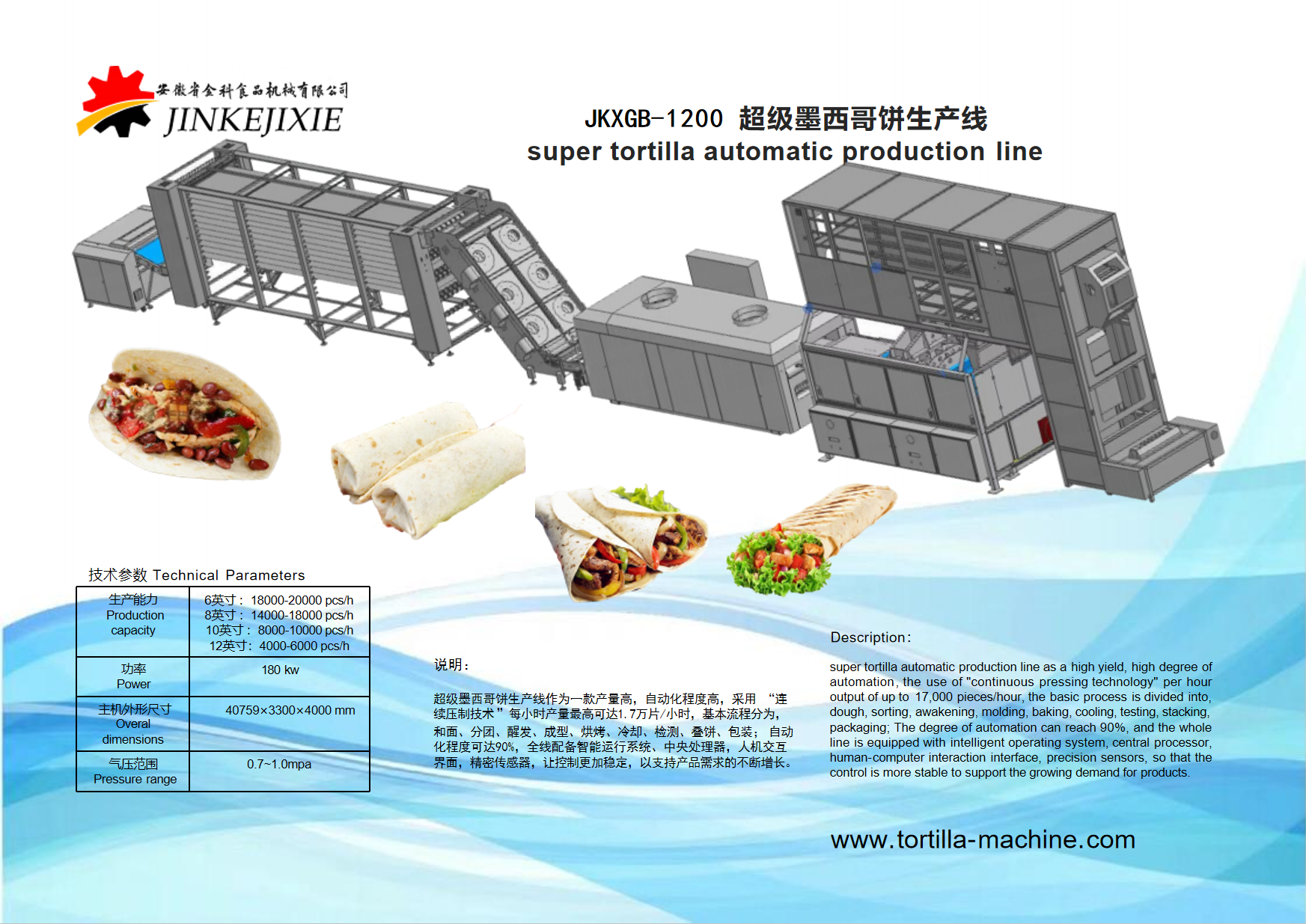

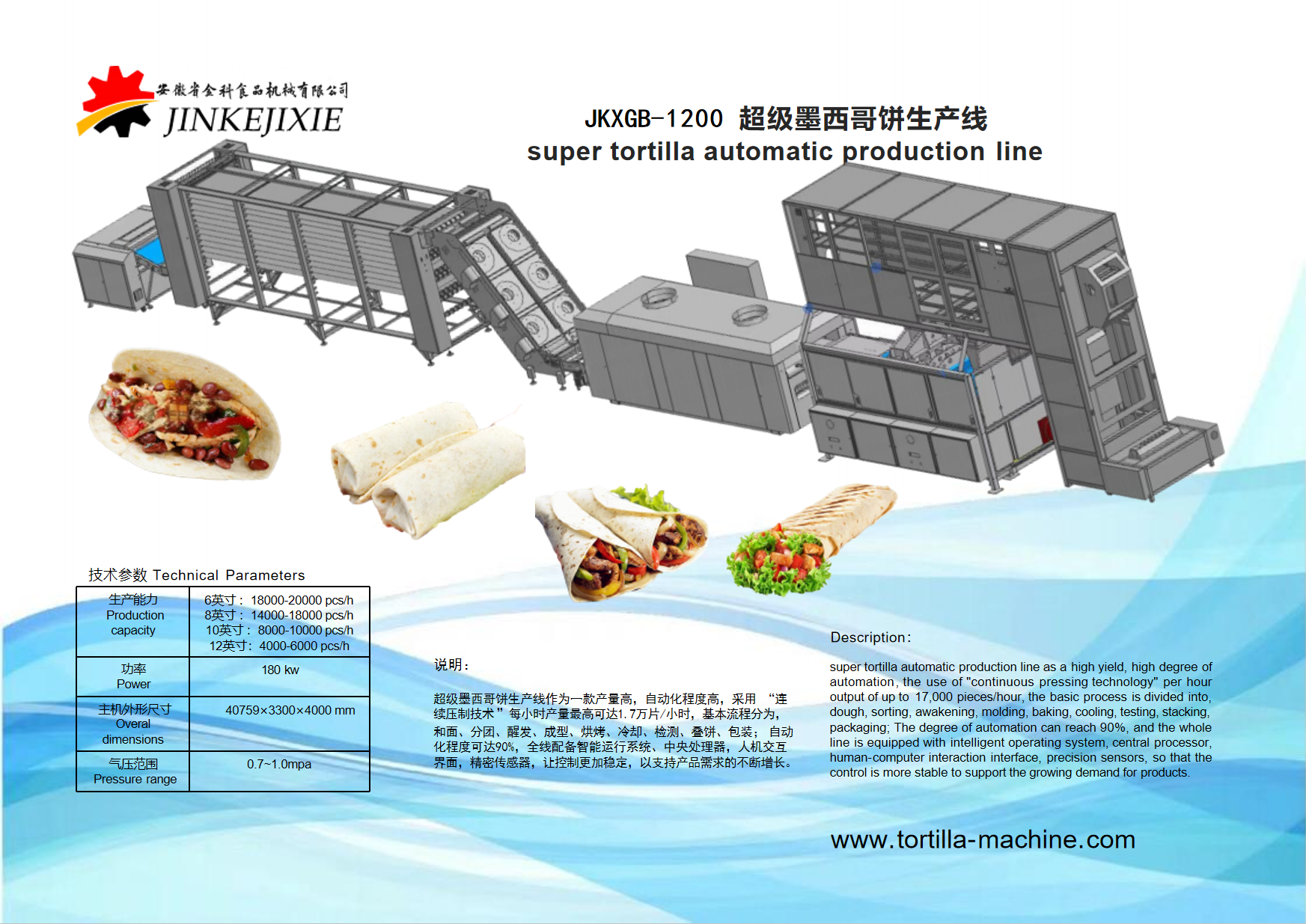

3.Overview of the Full-Automatic Tortilla Production Line

A full-automatic tortilla production line is an integrated system combining advanced equipment and technologies designed to efficiently and consistently produce tortillas. This production line automates the entire process, from raw material handling to final packaging, significantly improving production efficiency and product consistency.

Basic Components and Functions of the Production Line

A typical full-automatic tortilla production line consists of the following key components:

Raw Material Processing System: This includes the cleaning, dehulling, and grinding of corn. Automated equipment ensures precision and consistency in raw material processing, providing high-quality input for subsequent stages.

Mixing and Dough Preparation System: Ground corn flour is mixed with water and other ingredients through automated mixers to form a uniform dough. Automation at this stage ensures consistent dough quality, which is critical for producing high-quality tortillas.

Forming Equipment: The dough is then shaped into tortillas using a full-automatic forming machine. Automation in this process ensures uniformity in the size and thickness of each tortilla.

Baking System: The tortillas are baked using automated ovens that precisely control temperature and time, ensuring optimal texture and color.

Packaging System: Finally, the baked tortillas are quickly and hygienically packaged by automated packaging machines, preparing them for distribution. This reduces human contact and ensures product hygiene and safety.

4. Raw material handling in tortilla production lines

The selection and processing of flour are critical steps in the tortilla production process. High-quality raw materials directly influence the final product's taste, texture, and overall quality. Automated flour conveying and distribution systems play a pivotal role in maintaining the integrity and consistency of the flour from storage to the mixing stage. These systems ensure that the flour is handled gently to avoid damage to its delicate protein structure, which is essential for the dough's final quality.

5. Core equipment and technology of tortilla production line

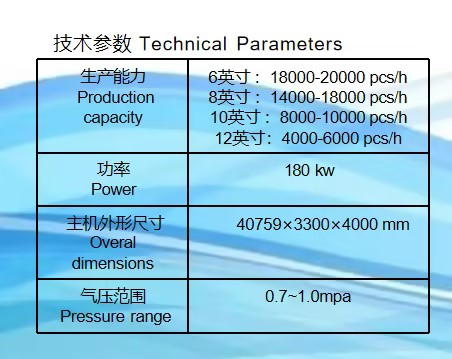

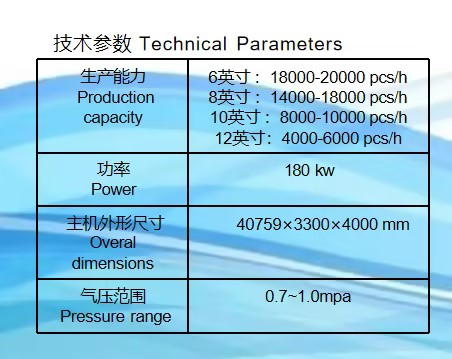

At the heart of an industrial-grade tortilla production line lies a suite of advanced technologies and equipment that ensure efficiency and superior product quality. The process begins with the preparation of dough, a critical step that utilizes high-precision machinery to mix and knead the ingredients to perfection. Following this, advanced forming technology shapes the dough into uniformly sized tortillas, ready for the next phase. The baking and frying process is controlled by automated systems that maintain precise temperature and timing settings, ensuring each tortilla is cooked to the ideal texture and crispness. Post-cooking, the tortillas move through automated cooling systems that rapidly reduce their temperature, preserving freshness before the final packaging stage. The right side shows our equipment parameters for your reference.

6. Capacity and Efficiency

Impact of Production Line Design on Capacity

The design of a full-automatic tortilla production line plays a crucial role in determining its production capacity. Key design elements such as the layout of machinery, the speed of individual processes, and the integration of various components all influence the overall capacity. For instance, optimizing the flow of materials from one stage to the next reduces bottlenecks, ensuring that the production line operates at maximum efficiency. High-capacity designs often feature multiple parallel processing units, allowing for simultaneous production steps, which greatly increases the volume of tortillas produced per hour.

Case Study: Enhancing Production Efficiency with Automation Technology

Automation technology significantly enhances production efficiency in high-capacity tortilla production lines. For example, a case study from a leading tortilla manufacturer shows how implementing automated quality control sensors reduced waste by 15% and improved production speed by 20%. The sensors ensured that only properly formed tortillas proceeded to the baking stage, reducing the need for manual inspection and reprocessing. Another case highlighted the use of advanced PLC systems that allowed for real-time adjustments to the baking temperature and time, resulting in a 25% increase in throughput without compromising quality. These examples illustrate how automation not only supports high capacity but also ensures that production remains efficient and consistent.

7. Quality Control and Safety Standards

In a full-automatic tortilla production line, key quality control points ensure product consistency and compliance with customer requirements:

Raw Material Inspection: Sensors check the purity, moisture content, and particle size of raw materials before they enter the production line.

Mixing Consistency Monitoring: Automated systems monitor the dough’s uniformity and viscosity during mixing to ensure consistent texture and flavor.

Precision in Forming: Automated forming machines use sensors to ensure each tortilla is consistent in size and thickness, reducing waste.

Baking Temperature and Time Control: The baking process is precisely controlled to achieve the desired color and texture for each batch.

Final Product Inspection: Before packaging, automated systems check the weight, appearance, and packaging integrity to ensure only quality products are shipped.

8.Technical support and services for industrial-grade tortilla production lines

Technical support and services are integral to the successful implementation and operation of an industrial-grade tortilla production line. The original factory price not only ensures cost-effectiveness but also comes with the assurance of direct support from the manufacturer. Training is a critical component of this support, equipping operators and maintenance staff with the necessary skills to manage the production line efficiently. Furthermore, after-sales service is vital for addressing any technical issues that may arise, ensuring minimal downtime and maintaining the production line's industrial-grade performance. The commitment to providing comprehensive technical support and services underscores the supplier's dedication to customer success and the longevity of the equipment.

9. Quality Control and Safety Standards

Quality Control Points in Automated Production Lines

In a full-automatic tortilla production line, key quality control points ensure product consistency and compliance with customer requirements:

Raw Material Inspection: Sensors check the purity, moisture content, and particle size of raw materials before they enter the production line.

Mixing Consistency Monitoring: Automated systems monitor the dough’s uniformity and viscosity during mixing to ensure consistent texture and flavor.

Precision in Forming: Automated forming machines use sensors to ensure each tortilla is consistent in size and thickness, reducing waste.

Baking Temperature and Time Control: The baking process is precisely controlled to achieve the desired color and texture for each batch.

Final Product Inspection: Before packaging, automated systems check the weight, appearance, and packaging integrity to ensure only quality products are shipped.

10.Summarize

In conclusion, the fully automatic tortilla production line stands out for its numerous advantages and significant market potential. This state-of-the-art technology offers a seamless integration of high efficiency, consistent product quality, and the flexibility to meet varying market demands. The importance of selecting a high-quality, high-capacity production line cannot be overstated, as it directly impacts the profitability and sustainability of a tortilla manufacturer's operations. By investing in an industrial-grade, fully automatic system, manufacturers can capitalize on the growing global demand for tortillas while ensuring the highest standards of production excellence.