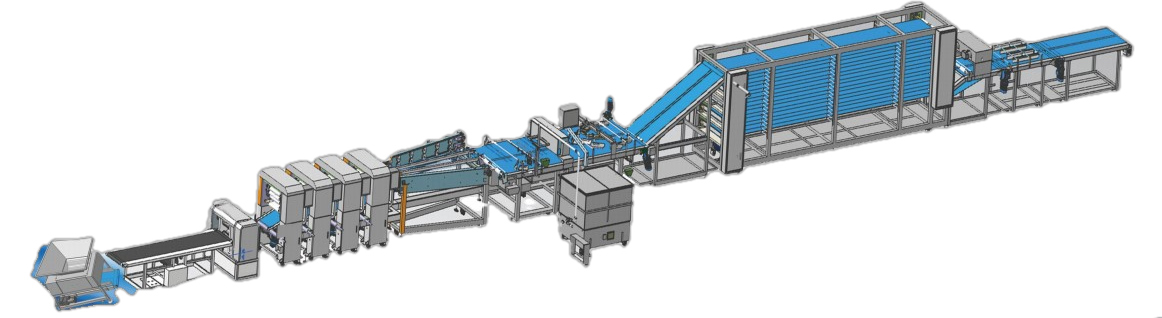

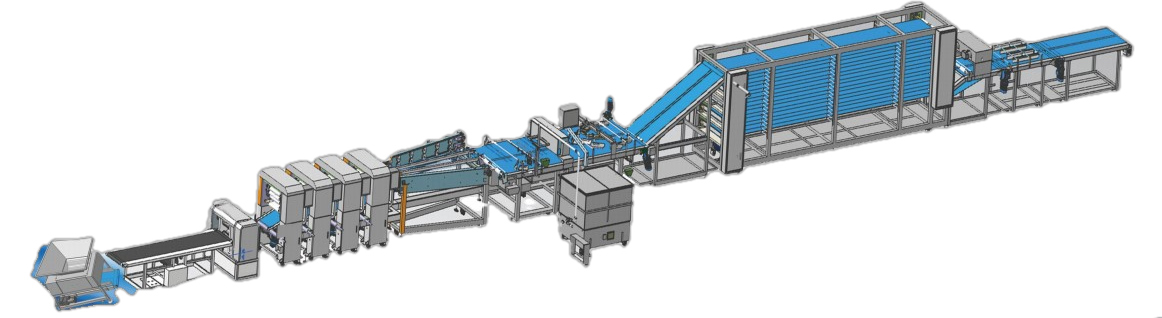

Introducing our state-of-the-art Automatic Indian Parotta Production Line. Designed to cater to the ever-increasing demand for Indian parottas, this advanced machinery is here to revolutionize your production process.

With a professional tone of voice, we proudly present a product description that highlights the key features and benefits of our cutting-edge production line.

Efficiency and productivity are at the core of our Automatic Indian Parotta Production Line. Equipped with the latest technology, this machinery ensures the effective production of Indian perottas, meeting the ever-growing food demand.

Our production line guarantees seamless operations, allowing you to streamline your manufacturing process and maximize output. With its automated functionality, you can expect consistent quality and uniformity in every parotta produced.

The precision and accuracy of our machinery ensure that each parotta is perfectly shaped, maintaining the authentic taste and texture that customers crave. Say goodbye to manual labor and hello to increased efficiency and reduced production time.

Safety is paramount in any production environment, and our Automatic Indian Parotta Production Line is designed with this in mind. Built with high-quality materials and adhering to strict industry standards, our machinery prioritizes the well-being of your workforce.

Investing in our production line means investing in the future of your business. With the ability to meet the ever-growing food demand, you can expand your market reach and cater to a wider customer base.

Choose our Automatic Indian Parotta Production Line and experience the perfect blend of efficiency, quality, and reliability. Elevate your production capabilities and stay ahead of the competition. Contact us today to learn more about this innovative solution.

1.Processing

Mixing flour - Dividing dough - Partitioning dough - Shaping into rounds - Allowing dough to ferment - Pressing dough in a heated mold - Baking dough on both sides in the oven - Cooling the crust - Packaging automatically

2.Parameters

| Model | JK-SZB-ⅡAutomatic Indian Parotta production line | Power | 23kw/380v50hz |

| Size | 27000×1200×800mm | Capacity | 3000-10000 pcs/h |

3.Feature

The food machine adopts PLC and touch screen memory function, and the whole food machine components are made of Delta, Siemens, Mitsubishi, Omron, NSK, etc., to ensure product stability. Simple operation, stable quality, range adjustment, production process automation, compact structure, stable performance, easy maintenance.

4.Purpose

Application Scenario: Manufacturing Quality Control Description: The Compatible Remote Control Multi Frequency High Frequency Customized Parotta Production Line is essential for manufacturing quality control processes. By utilizing this advanced remote control system, manufacturers can closely monitor and regulate the production of Parotta products to ensure consistency and accuracy. The high frequency capabilities of this customized production line enable real-time data collection and analysis, allowing for immediate adjustments to be made to maintain the highest quality standards throughout the manufacturing process.