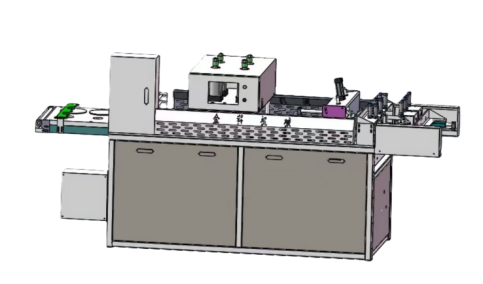

Introducing our Continuous Durable Mechanical Dough Laminating Machine, designed to streamline and enhance the dough laminating process in commercial kitchens and bakeries. This innovative machine is built to withstand continuous use, ensuring durability and reliability for your business.

One of the key features of this machine is its ability to laminate pancake dough with precision and consistency. The machine is equipped with advanced technology that allows for seamless and efficient dough lamination, resulting in perfectly layered and uniform pancakes every time.

In addition to its pancake laminating capabilities, this machine offers a range of other features to enhance your dough preparation process. From adjustable settings for thickness and speed control to easy-to-clean surfaces and user-friendly operation, this machine is designed to meet the needs of busy kitchen environments.

Invest in our Continuous Durable Mechanical Dough Laminating Machine and experience the benefits of improved efficiency, consistency, and quality in your dough laminating process. Upgrade your kitchen equipment today and take your pancake production to the next level.

1.Processing

Dough conveny press dough shaping upper and lower laminating

2.Parameters

| Model | dough conveny press dough shaping upper and lower laminating | Equirment size | 2700×800×1450mm

|

Production size | 12-25cm |

Power | 1.15kw |

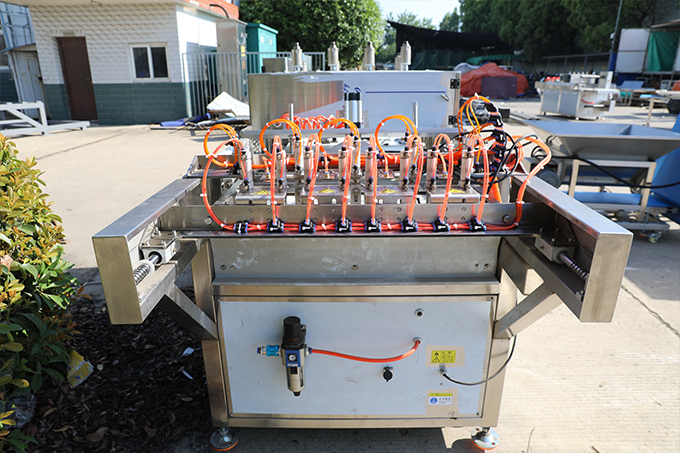

Pressure range | 0.8-1.0Mpa | Capacity | 1500-3000pcs/h |

3.Overview

Depending on the actual situation of the dough and the customer, the dough can be pressed multiple times, or multiple doughs can be pressed at the same time, and finally the film is covered up and down.

4.Feature

One of the key features of this machine is its ability to laminate pancake dough with precision and consistency. The machine is equipped with advanced technology that allows for seamless and efficient dough lamination, resulting in perfectly layered and uniform pancakes every time.

In addition to its pancake laminating capabilities, this machine offers a range of other features to enhance your dough preparation process. From adjustable settings for thickness and speed control to easy-to-clean surfaces and user-friendly operation, this machine is designed to meet the needs of busy kitchen environments.

5.Purpose

The Continuous Durable Mechanical Dough Laminating Machine is an essential component in a bakery production line, where it is used to efficiently laminate pancake dough. This machine can seamlessly integrate into the existing production process, ensuring a consistent and high-quality output of laminated pancake dough. With its durable construction and continuous operation capability, this machine is designed to meet the demands of a busy bakery environment, increasing productivity and reducing downtime.

6.Operate Guide(2-3 operators)

One person patrols the line, and another person places the finished product at the end of the production line to complete the entire production process, thus greatly increasing the production efficiency of the enterprise and reducing the production cost of the enterprise.