The automatic roti manufacturing system is a popular machine in the food industry. It efficiently carries out various steps like mixing flour, dividing dough, sorting, fermenting, shaping, baking, cooling, and packaging. This article aims to provide you with information about the automatic flour tortilla production system, hoping to be of assistance. Additionally, our company offers other food machines that perform similar tasks, including tortilla, pancake, pie, pita bread, burrito, taco, and flour production lines.

*The characteristics of the automatic flour tortilla production line.(1.Processing,2.Parameters,3.Overview,4.Feature,5.Purpose,6.Operation guide)

1.Processing

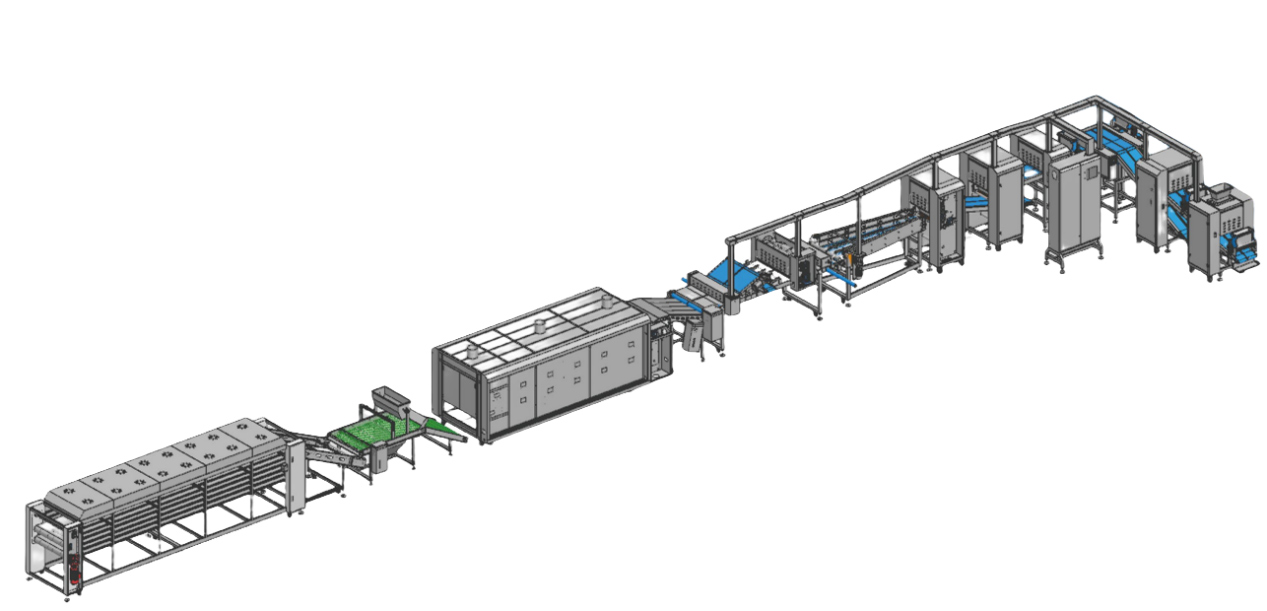

Flour mixer - dough partitioning - dough partitioning - dough Dough fermentation - hot press molding - oven double side baking - crust cooling - automatic packaging

2.Parameters

| Model | JKRTB | Power | 25KW |

| Size | 28,300 x5,800 x1830 mm | Capacity | 8000-10000 Pcs/H |

3.Overview

When the food processor is in operation, simply remove the dough from the mixer and place it into the dough dividing machine. The machine will automatically divide the dough into portions and allow it to ferment for approximately 5 minutes. The dough can then be transferred directly into the dough bucket and pressed into shape using the hot press molding machine. Afterward, the pie is baked on both sides in the oven. Once cooled, the pies are arranged and prepared for packaging. The key technical performance of this tortilla production line is on par with similar models worldwide. This food processor consists of a dough conveyor belt, dough dividing machine, fermentation machine, pie press, tunnel furnace, and cooling rack. The size and speed of pie production can be adjusted to meet specific production requirements.

4.Feature

The food machine adopts PLC and touch screen memory function, and the whole food machine components are made of Delta, Siemens, Mitsubishi, Omron, NSK, etc., to ensure product stability. Simple operation, stable quality, range adjustment, production process automation, compact structure, stable performance, easy maintenance.

5.Purpose

Restaurant Kitchen:

This Auto-feeding High Accuracy High Performance Roti Production Line is ideal for restaurant kitchens that require a high volume of roti production. With its automated feeding system, this production line can continuously produce roti with high accuracy and performance, ensuring consistent quality and efficiency in a fast-paced kitchen environment. The roti produced by this production line is perfect for serving customers in a timely manner, making it a valuable asset for any restaurant looking to streamline their roti production process.

Catering Events:

For catering events that require a large quantity of roti to be served to guests, this Auto-feeding High Accuracy High Performance Roti Production Line is the perfect solution. Its high accuracy and performance ensure that a consistent supply of freshly made roti is available throughout the event, allowing caterers to focus on other aspects of food preparation. The automated feeding system of this production line makes it easy to operate and maintain, making it a convenient choice for catering businesses looking to enhance their roti production capabilities.

Food Manufacturing Facilities:

Food manufacturing facilities that specialize in producing roti on a large scale can benefit greatly from using this Auto-feeding High Accuracy High Performance Roti Production Line. Its high accuracy and performance make it suitable for mass production, ensuring that a consistent supply of high-quality roti is available for distribution. The automated feeding system of this production line helps to streamline the production process, reducing labor costs and increasing efficiency in the manufacturing facility. With its advanced technology and precision engineering, this production line is a valuable asset for any food manufacturing facility looking to optimize their roti production operations.

6.Operate Guide(2-3 operators)

One person patrols the line, and another person places the finished product at the end of the production line to complete the entire production process, thus greatly increasing the production efficiency of the enterprise and reducing the production cost of the enterprise.