Introducing our state-of-the-art fully automatic chapati machine, designed to revolutionize your kitchen and streamline your chapati-making process. With this professional-grade appliance, you can effortlessly produce perfectly round and delicious chapatis, while significantly reducing labor costs.

Our chapati machine is equipped with advanced technology that ensures consistent and efficient performance. It effortlessly kneads the dough, rolls it into perfectly round shapes, and cooks them to perfection, all with just a push of a button. Say goodbye to the tedious and time-consuming process of making chapatis by hand.

Designed with precision and durability in mind, our chapati machine is built to withstand heavy usage in commercial kitchens, while also being suitable for home use. Its sleek and compact design allows for easy storage and maintenance, making it a must-have addition to any kitchen.

Not only does our fully automatic chapati machine save you valuable time and effort, but it also helps you cut down on labor costs. By automating the chapati-making process, you can significantly reduce the number of staff required, allowing you to allocate resources more efficiently and increase productivity.

Invest in our professional chapati machine today and experience the convenience and efficiency it brings to your kitchen. With its fully automatic features and labor-saving capabilities, you can elevate your chapati-making game to new heights while maintaining a professional standard.

Parameters

| Model | ZBSKXB | Power | 14KW |

| Size |

14,000 x3,000 x2330 mm | Capacity | 5000-9000 Pcs/H |

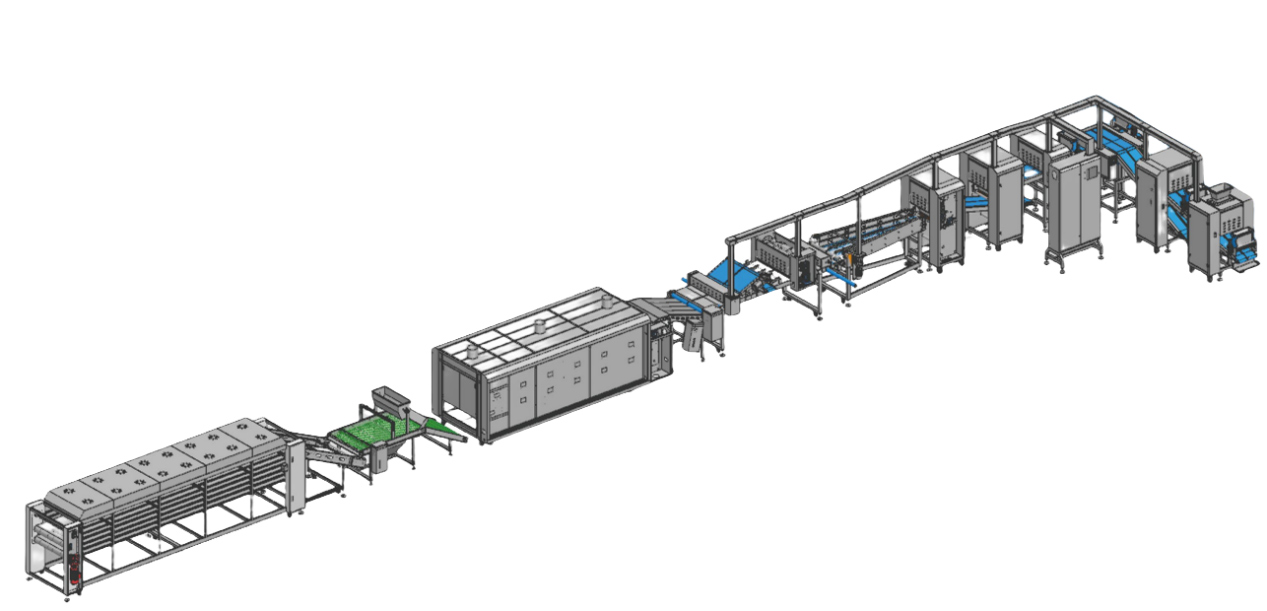

Overview

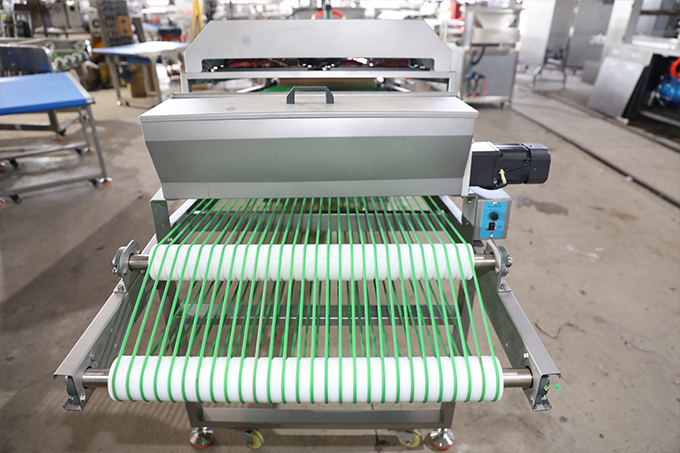

When the food processor is in operation, simply remove the dough from the mixer and place it into the dough dividing machine. The machine will automatically divide the dough into portions and allow it to ferment for approximately 5 minutes. The dough can then be transferred directly into the dough bucket and pressed into shape using the hot press molding machine. It is then baked in the oven on both sides. Once cooled, the pies are arranged and prepared for packaging. The key technical performance indicator of this tortilla production line is on par with similar models worldwide. This food processor consists of a dough conveyor belt, dough dividing machine, fermentation machine, pie press, tunnel furnace, and cooling rack. The size and speed of pie production can be adjusted to meet the specific production requirements.

4.Feature

The food machine adopts PLC and touch screen memory function, and the whole food machine components are made of Delta, Siemens, Mitsubishi, Omron, NSK, etc., to ensure product stability. Simple operation, stable quality, range adjustment, production process automation, compact structure, stable performance, easy maintenance.

5.Purpose

Restaurant Kitchen:

This Gravity Feed Professional Foldable Chapati Production Line is ideal for busy restaurant kitchens looking to streamline their chapati production process. With its efficient gravity feed system, this production line can quickly and consistently produce large quantities of chapatis to meet the demands of a high-volume restaurant. The foldable design of the production line allows for easy storage when not in use, making it a convenient and space-saving solution for restaurant kitchens.

Catering Events:

Catering companies can benefit from using the Gravity Feed Professional Foldable Chapati Production Line for catering events such as weddings, corporate functions, and parties. This production line can help caterers efficiently produce chapatis on-site, ensuring that guests are served fresh and delicious chapatis. The foldable design of the production line makes it easy to transport to different event locations, making it a versatile and practical tool for catering businesses.

Food Manufacturing Facilities:

Food manufacturing facilities can enhance their production processes by incorporating the Gravity Feed Professional Foldable Chapati Production Line into their operations. This production line is designed to meet the high production demands of food manufacturing facilities, allowing them to produce chapatis in bulk with ease. The gravity feed system ensures a continuous flow of chapatis, increasing efficiency and productivity in the manufacturing process.

School Cafeterias:

School cafeterias can benefit from using the Gravity Feed Professional Foldable Chapati Production Line to efficiently produce chapatis for students. This production line is easy to operate, making it suitable for cafeteria staff with varying levels of experience. The consistent and uniform chapatis produced by this production line can help ensure that students are served high-quality and nutritious meals during school hours.

6.Operate Guide(2-3 operators)

One person patrols the line, and another person places the finished product at the end of the production line to complete the entire production process, thus greatly increasing the production efficiency of the enterprise and reducing the production cost of the enterprise.