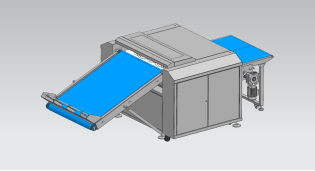

The Quick Fully Automated Multi Function Flatbread Counter Stacker is a cutting-edge piece of equipment designed to streamline the production process in commercial kitchens and bakeries. This stacker is specifically engineered to efficiently stack flatbreads and other dough-based products with precision and speed.

With its fully automated functionality, this stacker eliminates the need for manual labor, allowing for increased productivity and consistency in stacking. The machine is equipped with advanced technology that ensures each stack is perfectly aligned and uniform in height, resulting in a professional presentation of the finished product.

In addition to its stacking capabilities, this multi-function stacker can also handle a variety of dough types and sizes, making it a versatile tool for any food production operation. Its user-friendly interface allows for easy customization of stacking patterns and settings, giving operators full control over the stacking process.

Overall, the Quick Fully Automated Multi Function Flatbread Counter Stacker is a reliable and efficient solution for businesses looking to streamline their production line and improve the quality of their finished products. Its innovative design and advanced features make it a valuable asset for any food service establishment.

1.Processing

At a large-scale bakery, the Quick Fully Automated Multi Function Flatbread Counter Stacker is used to streamline the production process of flatbreads. As the flatbreads come out of the oven, they are automatically stacked by the machine, eliminating the need for manual stacking. This not only increases productivity but also ensures consistent stacking quality, resulting in a more professional end product.

2.Parameters

| Model | JKDBJ | size | 2645*1890*1185 mm |

Power | 3kw | Capacity | 6000-9000 Pcs/Hour |

| Pressure | 0.7-1.0 Mpa |

|

|

3.Feature

The food machine adopts PLC and touch screen memory function, and the whole food machine components are made of Delta, Siemens, Mitsubishi, Omron, NSK, etc., to ensure product stability. Simple operation, stable quality, range adjustment, production process automation, compact structure, stable performance, easy maintenance.

4.Purpose

Stack dough

5.Operate Guide(2-3 operators)

One person patrols the line, and another person places the finished product at the end of the production line to complete the entire production process, thus greatly increasing the production efficiency of the enterprise and reducing the production cost of the enterprise.